We came to a major decision this past week – the 2,500 pound, 135 horsepower, propane-fueled, hydraulically powered hexapod robot will be named… Stompy.

(It was a close thing, to be sure. We were split 10 to 8 between Stompy and Fluffy. Stompy seemed more unique and somehow more appropriate, though).

Today’s class was largely a workday. Dan gave a presentation on an introduction to controls systems and, specifically, the choices we’ve made thus far to ensure robust control of the hexapod. The controls group then chugged away at the Leg Cart simulation, while the mechanical group hit up the welding shop for a blitz of manufacturing. I think/hope we’re about a week away from assembling the full Cart, but we’ll see how it goes this weekend.

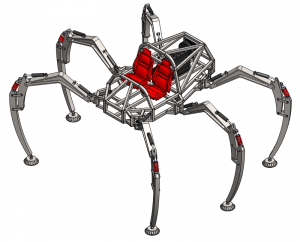

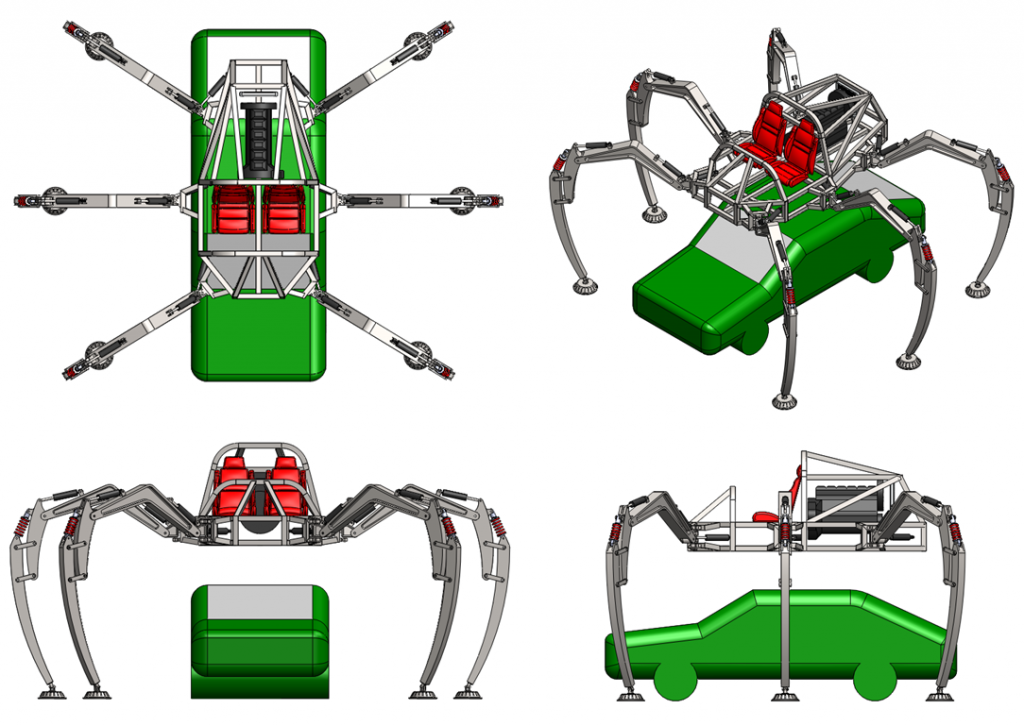

One big thing that got done – I finished the first round of concept art for the project. Given the parameters we’ve been working so far, the design techniques we’re aiming for, and the major components we’ve selected, I give you a first glimpse at Stompy:

Note the two seats side by side. This is no solo ride.

You may be confused as to how large this robot is. The distance between the centers of the two middle legs, folks, is currently 17 feet. That’s about a lane of traffic… and a half. The bottom of the frame is over 6 feet off the ground. To give you an idea of how big that really is, check out this comparison to a shoddily rendered version of my car.

Stompy is coming, folks. Get ready.

Fantastic! I feel like Stompy could inspire a whole line of bumper stickers — “I’d rather be stomping”, “This IS my other car”, etc.

“My Other Car is a Hexapod”

My other car could step on yours.

Where could you drive it around to test it? I assume it’s not, erm, road-legal. So cool! Imagine taking it to a big open space like a farm or a vehicle testing range and running around!

Someone asked this question the first day of class. We all pretty much responded “Wherever the hell it wants to go!” in unison.

You mean, stomping around! ^^

Central square. Definitely.

Add a magnet underneath and you can pitch it to a transit department as a “parking obstruction remover” (as long as it can pick up a car and re-arrange it into a correct parking or towing position).

;-P

PS

Good Luck!!

If towing, you could leave a card stating: “you´ve been stomped!”

Please make sure you leave a place to put some Truck Nuts….That is all.

Note the conspicuous lack of controls in that rendering. I know better than to chalk it up to oversight.

You’re building an autonomous death robot, aren’t you?

<.< >.>

Noooo…

Actually more like remote control. It’s better for pranking that way.

Wild Wild West with Will Smith anyone…Dr. Loveless builds the giant spider machine to conquer the North 😎

One thing missing. last line is better if you include mad scientist laugh.

“Stompy is coming, folks. Get ready. Muahahahahahha!”

It’s been done since the 60’s.

Other than the one below, what is the function?

http://www.youtube.com/watch?v=ftV2HeKPeBM&feature=endscreen&NR=1

Well, note that this is a class project at Artisan’s Asylum, a makerspace in Somerville, MA. The function of the robot first and foremost is to train all of the students in the class in how to become roboticists capable of working with large, high performance hydraulic and electric systems, outside of high school, college or any standard educational experience. To that end, the project is succeeding marvelously.

Past that, the purpose is to create a machine that’s engaging to the public eye and imagination, and to open-source the technology required to make machinery on this scale. Hobbyists and amateurs largely stay away from this type of technology because there isn’t a lot of publicly accessible information about it.

Ultimately, we’ll have any amazing machine that our hometown is proud of, and we’ll enable a whole new generation of makers and builders.

As a disabled individual I think this project has the potential to morph into a commercially viable product which will enhance the mobility of the disabled. Of course the design would need to be smaller in all respects. The ability to go up and down grades (ramps and steps) and over objects would make it a huge advancement over wheelchairs and scooters. Perhaps your next iteration could be single passenger. It could use some of the power and technology more on the scale of lawn tractors and using some of their technology for power and hydraulics. Name it the PowerWalker?

Childhood memories of Horrible Hamilton come to mind.

Actually, beyond the mere because-we-can thing, are there any particular environments this type of vehicle would be advantageous for? How about in a swampy wooded area? How about in rocky or mountainous terrain?

How about at the polar regions of the Moon, where the terrain is supposed to be very uneven? Also, this thing might even be able to leap over some obstacles in the lower lunar gravity.

Legs, in general, are far more capable in rough terrain than wheels or tracks. Note the shock absorbers in the model – we’ll be sensing force on each leg, and will be able to clamber over arbitrarily broken terrain.

In all seriousness, this could make for one of the best disaster recover vehicles ever made. The legs are essentially excavator arms – if they were actually made into excavator arms, the thing could walk and dig anywhere it wanted, no matter the state of decay of the urban environment.

Spoken like someone who’s never had to help get a stuck horse out of a swamp. You’ll want some sort of optional (inflatable? foldable?) pad that you can deploy on the feet for use in swamp and quicksand.

I think we’ll just be trying to steer clear of swamps and quicksand…

You can add small wheels on front and back legs. And use middle for breaking and propulsion. This cheap upgrade will make it more drivable 🙂

Yep could i have some fun with that even more if each foot was say 100lb in weight then stompy yep more like stomper ..

Can’t wait to see the hydraulic schematics for this thing… if they want fully independent control, that’s going to be one hell of a valve block…

18 proportional valves 🙂

Am I the only one who’s mind went first to thoughts of where you could fit a turret and other implements of Doom on Stompy? (possibly Nerf or water balloon Doom, but Doom nonetheless)

Haa, Haa, my hexapod is actually named Fluffy —

http://shoreline.patch.com/articles/experiments-galore-at-room-nine-math-and-engineering-fair#video-9271910

Could you put wheels on the legs, and make it into a *skating* robot?

Have you got a simulation of the gait set up for the control loop, or is this going to be a one-actuator-on-one-leg-at-a-time slow moving thing like those that occasionally show up at Burning Man and the like (other than ones using an upscaled Theo Jansen’s Mechanism)?

We sized the powerplant (135 HP propane engine driving a 50 HP hydraulic pump) to allow for walking at parade speeds at the scale we’re talking about. The robot is being designed for 18 degrees of freedom, which will allow for multiple legs to move at one time (though completely independently). This is absolutely not a Theo Jansen mechanism.

We as instructors have a baseline simulation for a tripod gait right now, but our students will be optimizing the gait for the actual mechanical design.

Way cool guys, best of luck! You really should try to get it out to Burning Man!

I love it. I have always wanted to do a project like this. One addition I had thought about is add electric driven wheels at each foot. Each wheel could rotate 360 degrees. Then it could wheel and walk in any direction. The wheels could retract to walk on feet.

Does it come with BLASTERS? Revere Beach needs some excitement!!!

I want one!!!

Looking at the concept art It looks like there is no reason why it couldn’t drive to it’s stomping ground. Something like integrating it with go-cart mechanics that can handle the weight.

That’s a good idea. If the legs could fold upwards far enough you could have a detachable wheeled base that would let it drive around under it’s own power, then it could stand up and walk away.

Getting it street legal might be a stretch, but it would certainly be convenient if it was.

If you build a tachikoma, I’ll buy one.

Mud is easy. Use an elephant foot – a simple mechanical arrangement can cause the foot to spread when weight is placed on it, and shrink when weight is removed. If the ankle and foot are crenelated and perforated, this too will prevent suction problems.

A Theo Janssen-style robot would be easier and still almost as impressive. Good luck!

It’s a real life SpiderZoid! http://farm2.static.flickr.com/1308/4688854580_5d5d3d983d.jpg

Make sure it has seatbelts. Seriously. And a kill switch within reach of anybody on it.

Personal experience in a simulator.

It looks incredibly cool, by the way.

Way cool! I’m curious about the power module. Why propane? From the rendering, it looks like an inline six. Why not a gas turbine? And being a Citroen owner, I’m curious about the hydraulic system. What kind of pump and accumulator did you folks use? Can’t wait to order one at my friendly neighborhood Stompy Dealer!

It’s a propane-powered system because we’re trying to operate both outdoors and indoors for a limited amount of time – propane burns cleanly enough that that’s a possibility, and gas and diesel don’t. It’s an inline 6 because we pulled a hydraulic powerplant out of a giant forklift, which was designed to operate both indoors and out. Electric actuation isn’t a possibility due to the scale and stance of the vehicle.

We’re using a fixed displacement gearpump with a bleed valve. We haven’t sized an accumulator just yet, but the low pressure reservoir is open to atmosphere.

Nice re-use of the power unit. Citroen cars use a much smaller hydraulic system than yours, but at similar working pressures. The pump is a piston type, and is only called into action via a clutch when the accumulator runs low and calls for more. The reservoir is not under pressure, like yours, but only holds several liters of fluid.

Great! It would make commuting on the SE Expressway more reliable: just straddle the cars and keep on going when traffic halts.

Minor kvetch: “Stompy seemed more unique” — “unique” is absolute; like “unanimous”, you can’t be more or less.

Around here a 17 foot span would literally take the whole road. A lot of Providence is based on colonial pathways.

This is awesome!

I’m a fan of big robots,and the PSoC1/3/5 (worked on it for very long,and not seen such an implementation!)

Really interested to see how this goes for you.

Wish I could contribute,but living in South Asia makes makes it only something I can express in this comment.

All the best guys!

Hopefully we’ll see you at Burning Man this year with this mad project. Very cool!

Seriously! A Stompy, acting like an ambulance, can avoid the traffic jam in a car crash to rescue wounded people.

How is it on gas?

If our predictions hold up, about 4 or 5 gallons to the mile!

Do you think you could use modern (metric) measurement units for this globally accessible webpage? We all know what happened when NASA insisted on ramming some medieval units into their space program… whoops! Completely missed what we went to see! It just seems bizarre to your website visitors that you’d be developing something modern using stone-age units we don’t understand. Don’t get me wrong – I think this is a really cool concept. But really, folks, this is the 21st Century. Get up to speed.